The challenge

Forming part of routine maintenance works, Network Rail needed to carry out a series of repairs to p-way assets within the London and Croydon area, bringing them up to full compliance. In order to mitigate the chances of these works disrupting the nearby infrastructure, signalling specialists were required to support the p-way team by carrying out a comprehensive programme of testing.

The solution

Working directly for Network Rail as part of their CP6 Minor Signalling Framework, in 2023 Amaro was instructed to provide ongoing S&T support for the client’s in-house p-way maintenance teams as they worked throughout the London and Croydon area repairing defects across a range of assets.

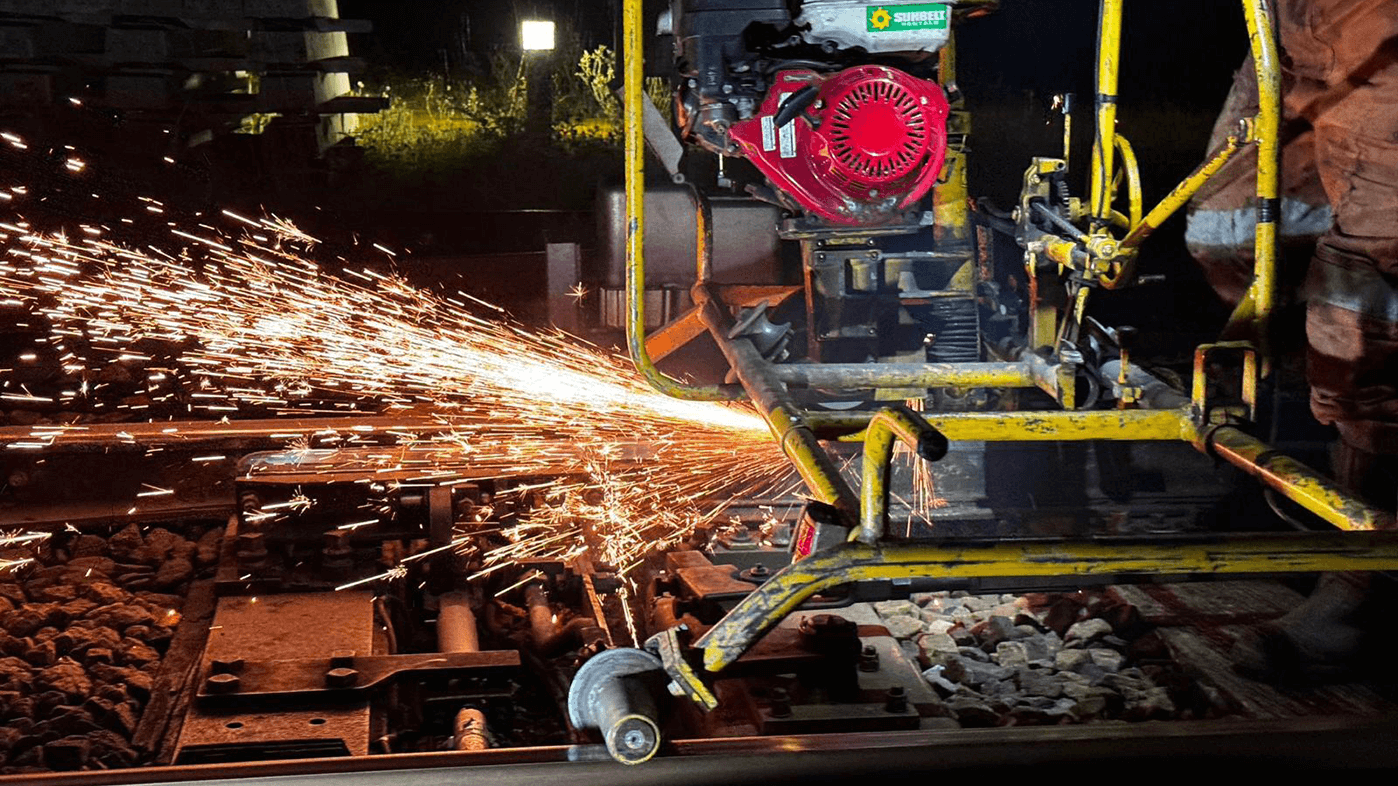

Covering activities such as stressing, tamping, welding, and points maintenance to name a few, a highly capable three-strong team made up of one SMTH and two installers carried out the following approved tests whilst specific p-way tasks were being performed:

P-Way Works Tests Performed

- Tamping/tandem tamping works: FPL (facing point lock), PF01, SMS001, SMS011

- LHR, RHR (left-hand rail/right-hand rail): Edilons, Track circuit test (TC00)

- Stress on points: FPL (facing point lock), PF01, SMS001, SMS011, TC001

- Welding temp joints: TC00

- Weld for crossing changeovers: TC00

- Points grind repair (removing motion units): FPL, SMS001, SMS011, PF01, PA04

- Grinding works (FPL and adjustment if required): FPL, SMS001, SMS011, PF01, PA04

- Half set and full set: PA01, PA04, PB03, PB04, PB06, TC00

- Changing IBJs: TC00

Prior to any works taking place, our SMTH would explain the p-way works covered in that shift’s maintenance test plan, before detailing the exact tests that would need to be delivered at each and every location.

With the briefing complete, the PIC/SMTH would then inform the signaller of their intention to work in the area, explaining exactly what equipment may be affected, and providing their contact details. Again, prior to any works taking place, all of this equipment was thoroughly tested with the signaller to confirm that the signalling system was operating as it should.

Once permission had been granted, Amaro’s team got to work ensuring the correct functionality of all signalling equipment following the shift’s repair works, putting an immediate hold on all operations should wire degradation be discovered during an installation.

With all testing activities complete and the signaller having confirmed that no other nearby equipment was showing as occupied, a comprehensive shift report was submitted, clearly detailing the works undertaken, as well as any defects or other issues identified whilst on track.

Delivering added value

In addition to the site-based activities, our in-house planning team produced all of the necessary safe work packs, attended project planning meetings, and liaised directly with Network Rail, consulting Routeview and AIVR software to identify opportunities to access specific location cases on a separated basis, thereby minimising the impact upon the signaller’s workload.

What’s more, if planned works could not be undertaken for any reason, our SMTH actively sought to identify any other maintenance activities required nearby, helping to reduce the number of non-productive shifts, and removing unnecessary costs, tasks and pressure from Network Rail’s infrastructure maintenance engineers.

The outcome

Whilst works are very much ongoing, the testing and p-way works carried out by both parties have already helped facilitate larger numbers of higher capacity trains, not to mention the removal of speed restrictions, and a reduction in delays, resulting in a faster, more reliable service for passengers.